Multi Axial Cubical

Need and Scope:

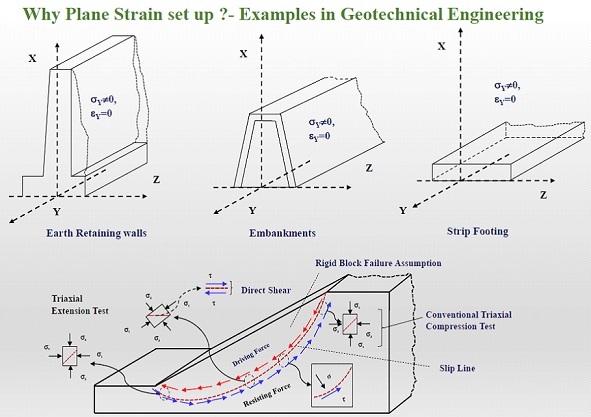

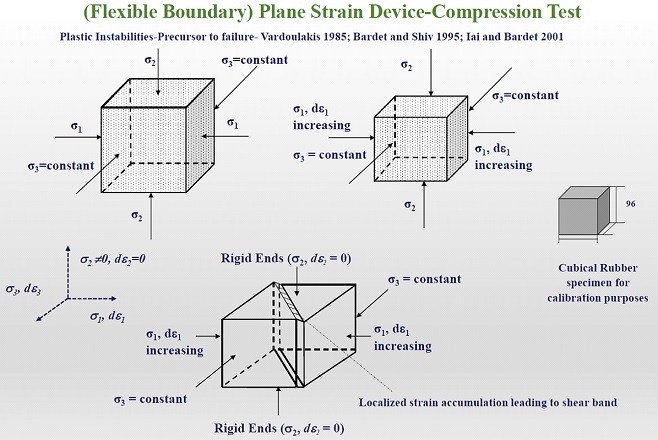

This setup can also be called Flexible Boundary Plane strain setup. Why Plane strain testing conditions.

Concept:

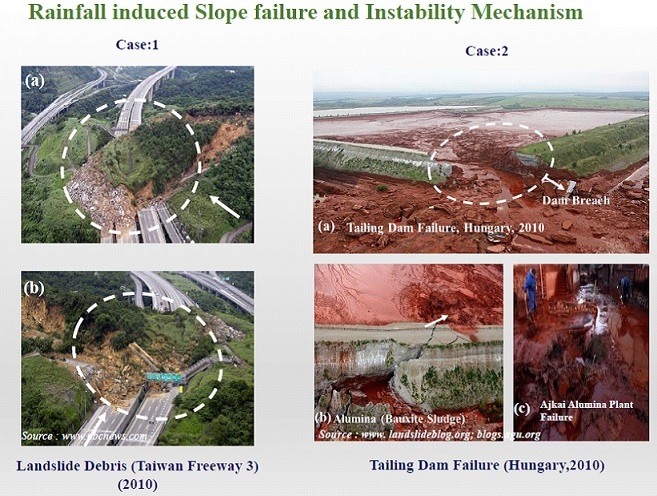

The magnitude and orientation of the principal stresses acting on a soil element can change with the loading situation. Conventional triaxial testing on cylindrical specimens is often used to study the stress-strain behavior of soil in the laboratory. However, the soil element is only subjected to axi-symmetric state of stress in this type of testing. A Multi-Axial Cubical setup with independent control of the three principal stresses can evaluate the effect of intermediate principal stress (2) on the mechanical behavior of soil. It is important to study the effect of 2 the yield and failure behavior of soil to accurately model certain boundary value problems associated with slope stability and foundation design.

Multi Axial Cubical

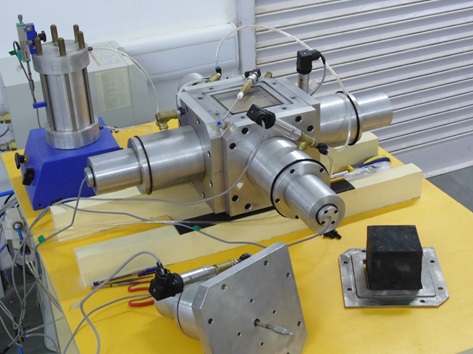

Experimental Setup:

The Multi-Axial Cubical setup comprise of an aluminum space-frame and the flexible boundaries are made of butyl-rubber. These flexible boundaries (rubber membranes) distinguish the set-up from all other existing plane strain devices. Several researchers have tried to minimize the friction at the boundaries by making them lubricated end with silicone grease. A device on similar lines was developed by Arthur et al. (1981) with the shear-stress also applied at the boundaries depending on the normal stress applied. However, one of the limitations of the set-up was it was stress-controlled and hence it could capture the post-peak response of the material. In the present device, normal stresses are only applied on the face of the cuboidal specimen and due care is taken to have negligible shear stress at the interface of the flexible boundaries and the soil specimen (unlike in conventional triaxial test, where shear stresses develop in between the rigid porous stones and the soil sample). Instability of geomaterials is greatly affected by the boundary conditions and a detailed comparative study of instability analysis under both rigid and flexible boundary conditions is carried out by Mukherjee et al. (2016). Thus, lies the justification monitoring the soil response in flexible-boundary plane strain condition. A custom made steel mould has been casted for preparing these rubber membranes. Utmost care was taken to minimize the stress-concentration at the corners of the rubber membranes by rounding the corners slightly rather than a sharp edge.

The aluminum pressure housings (on four faces) as depicted in Figure comprise of a Linear Variable Differential Transformer that is fixed inside it (LVDT- 50mm) which measures the deformation at the face of the sample at its center. The pressure housings also comprise of pressure transducers (capacity 0-800kPa) on their sides for measuring the normal stresses at the two faces. The pressure housings are fused using a transparent pipe in order to maintain the equilibrium pressure in a particular axis. As a part of the development of the setup, a volume-change device has also been developed in-house. The set-up also has the provision of measuring the external pore-pressure and the internal pore-pressure at the center of the cubical sample of dimension 96 x 96 x 96 mm.

It is fully automated with pneumatic controls and two electro-pneumatic transducers are used to control the two separate principal stresses (?1 and ?3) maintained in the two mutually perpendicular axes. Data Acquisition System (NI-DAQ 6363) is used for reading the analog signals of the sensors as well as for controlling. Visual programming language compatible with the DAQ, NI-LabVIEW 2010 is being used for developing the software. Various stages of soil testing viz. saturation, consolidation and shearing are made automated with the integration of these sensors and controlling them using LabVIEW. The minor principal stress (?3) is stress controlled while the major principal stress (?1) is maintained by stain control. For this a feedback mechanism is used in terms of PID (Proportional-Integrator-Differential) control. The choice of the PID parameters and their fine tuning is essential for proper control of the system.

Multi-Axial Cubical Setup